EEC - Elevator for Confined Space

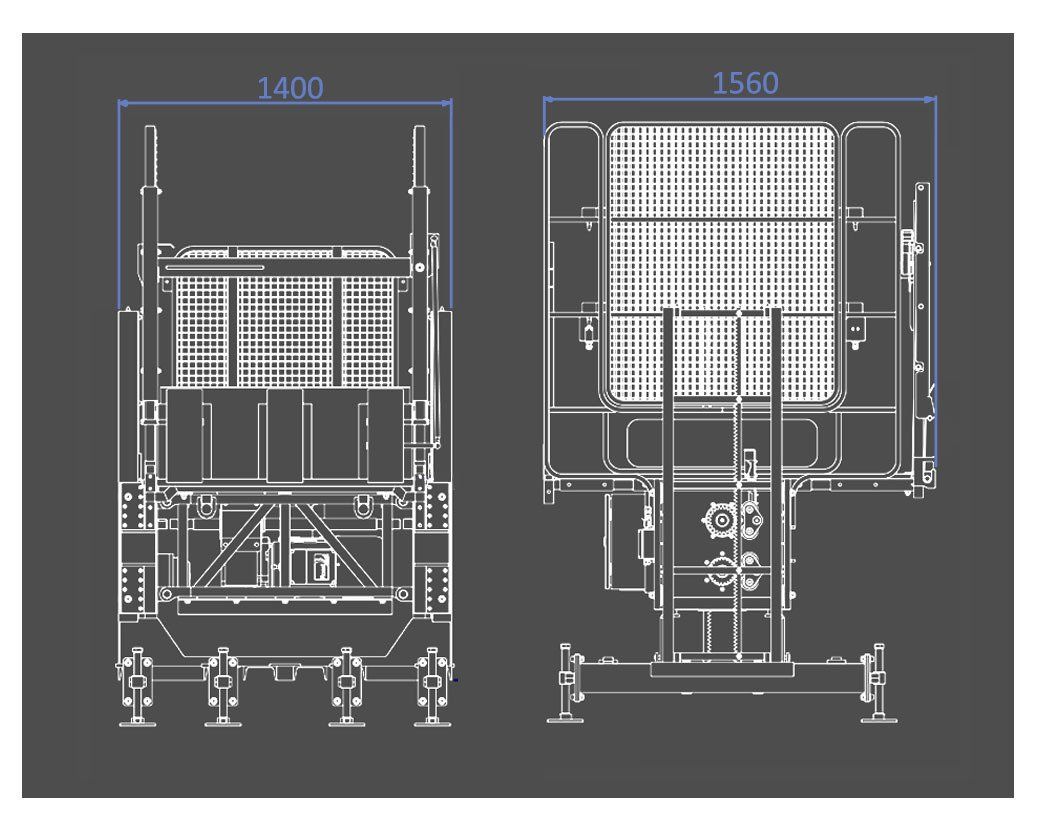

The EEC is the only fully removable rack-and-pinion forklift type lift on the market, allowing it to be introduced through reduced gaps of up to 600x600mm.

Reduced access, doors, windows, or manholes are no longer a problem that limits the installation of lifting equipment.

Once inserted, and mounted inside (basic mechanical assembly) allows us to work with a large load capacity (750Kg - 1,500Kg)

Innovation and performance at the hand of the building.

This team apart from the great reception it has had in the industrial sector, has been the building who has seen the great advantage it introduces in the sector due to the following factors:

- The equipment allows its installation in the elevator shaft, taking advantage of the natural work space for distribution of material, in height.

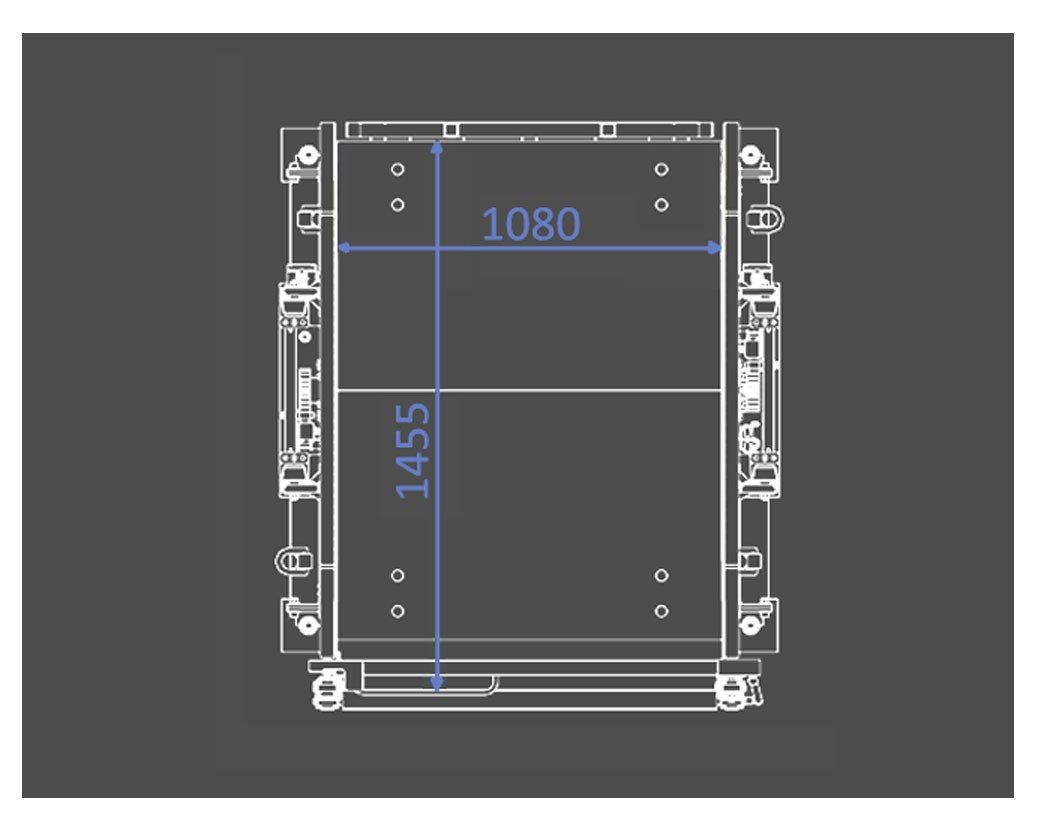

- Unique in loading area, this equipment really takes advantage of this space, with an interior loading area of 1,455x1,080mm. (in standard configuration) allowing the introduction of European pallets with a pallet truck.

- Landing in finished slab, by having the motorization at the bottom and growing in height as the work progresses, allows us to always disembark in the last finished slab.

- Maximum duration on site. The equipment allows its installation from a very early stage and can reside on site even until after the installation of the final elevator doors, being able to remove it disassembled just before the installation of the elevator.

- Constructive advantage allowing to finish off the facades and roof, by being able to distribute from this central point (instead of with equipment or access from the facade). In this way, costs are saved and qualities in the finish are improved, avoiding subsequent finishing.

- Installation in interior patios, stairwells and other points of difficult access and in need of load capacity.

- Climbing speed: 22m./min.

- Lifting height: 75m.

- Load capacity: 750Kg. or 1,500Kg. (double configuration).

- Possibility of incorporating keypad per plant (from any plant we can send to any plant)

- It incorporates a PLC and frequency variator, for regulation of parameters as well as incorporating by default starting and braking ramps.

- Parachute brake.

Added value and versatility.

There are already many construction and rental companies that enjoy the advantages offered by an innovative and differentiating team like this.If you want a real competitive advantage in your company, incorporate teams that make a difference like the EEC.